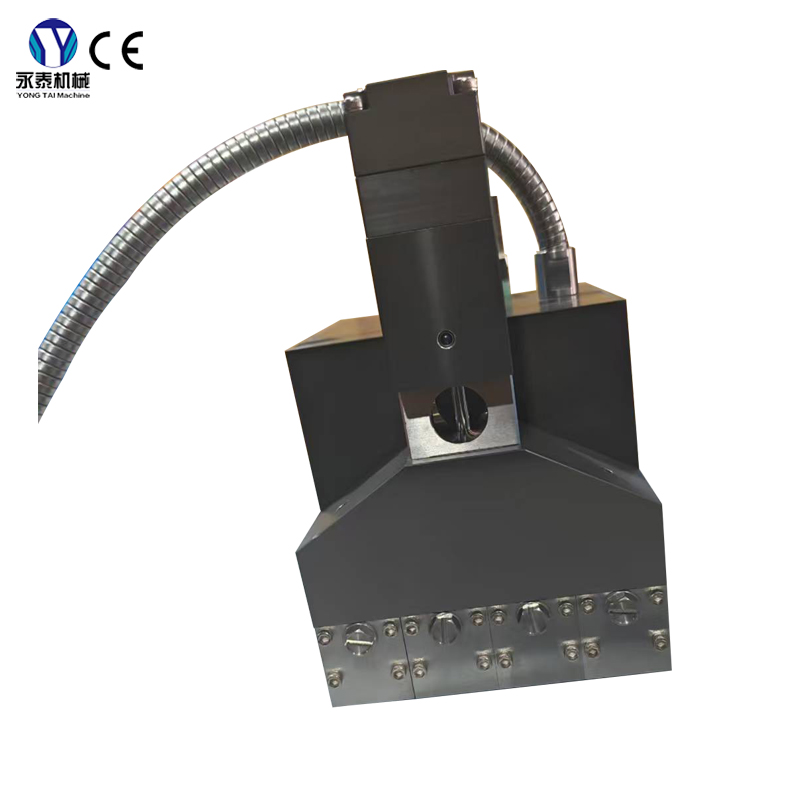

The fiber spray gun is a kind of industrial equipment specially used for hot melt adhesive spraying and composite material production. Its core parts are mostly made of imported materials and have the characteristics of realizing glue spraying and anti-corrosion.

Brand:

Yongtai machineOrder(MOQ):

1Product Origin:

Fujian,ChinaColor:

SilverShipping Port:

XIAMEN PORTLead Time:

20

Working principle: When the anti-pumping fiber spray gun is working, when it is necessary to stop spraying glue, the solenoid valve will start the anti-pumping module to reversely pump back the hot melt adhesive in the nozzle channel. In this way, the hot melt glue is prevented from continuing to flow out after the glue spraying is stopped, and dripping, tailing and other phenomena are avoided, thereby achieving instantaneous glue cutting and keeping the glue line neat.

Structural design

Gun body: usually made of high-temperature-resistant materials, such as imported high-strength engineering plastics or metal alloys, which can withstand long-term high-temperature environments and ensure that the spray gun will not deform even when used at 300°C.

Back-drawing module: It is a key component to realize the back-drawing function. It has special channels and structures inside, which are connected with the solenoid valve and the nozzle. When the solenoid valve is triggered, the back-drawing module can generate reverse suction to draw back the excess hot melt adhesive in the nozzle.

Solenoid valve: controls the startup and shutdown of the back-pumping module, and accurately controls the timing and intensity of the back-pumping to ensure the glue cutting effect. At the same time, the quality and performance of the solenoid valve also directly affect the service life and stability of the spray gun.

Nozzles: There are many types and specifications to choose from, such as spiral, strip, dot, mist, fiber and other nozzles with different glue dispensing methods, which can meet the diverse needs of different industries and production lines such as electronics factories, food factories, packaging plants, and diaper production.

Application areas

Hygiene products industry: In the production of disposable baby diapers and adult diapers, the sizing and spraying process used on leg elastics and three-dimensional protective elastics can accurately control the amount of glue and the shape of the glue line, ensuring the firm fit of the elastic and the main body of the diaper, while ensuring the comfort and appearance quality of the product.

Packaging industry: It can be used for gluing operations such as edge banding and sealing of various packaging materials, such as carton sealing, plastic bag sealing, etc. It can achieve fast and even gluing and improve packaging efficiency and quality.

Other industries: It is also widely used in fields such as the pasting of trademark labels and gluing during product assembly, providing efficient and precise gluing solutions for the production of various products.

The following picture shows the gluing pattern of fiber misting nozzle:

The coating width of this nozzle can meet your requirement because it can be designed accotrding to the dimension fo your products.