Laser glue edge banding machine is a device that uses laser technology to perform edge banding. It uses the heating effect of the laser to achieve seamless connection between the edge banding and the board, without the need for traditional hot melt glue or adhesives. This edge banding technology has the advantages of high efficiency, environmental protection, and seamlessness, and is widely used in furniture manufacturing and other fields.

Brand:

Yongtai machineItem NO.:

YT-FB100Order(MOQ):

1Product Origin:

Fujian,ChinaColor:

WhiteShipping Port:

XIAMEN PORTLead Time:

20Equipment highlights:

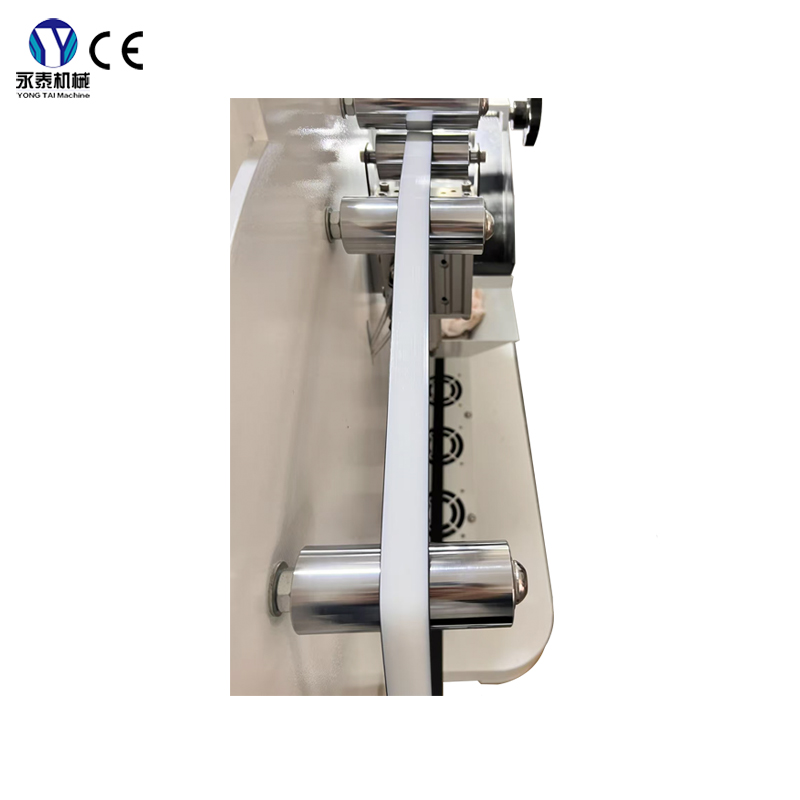

1. Reasonable mechanical structure and exquisite appearance design. Segmented configuration allows for easy placement of equipment.

2. Segmented vertical screw machine for more uniform color matching. Accurate temperature control, fast glue melting speed, and minimal waste during glue replacement.

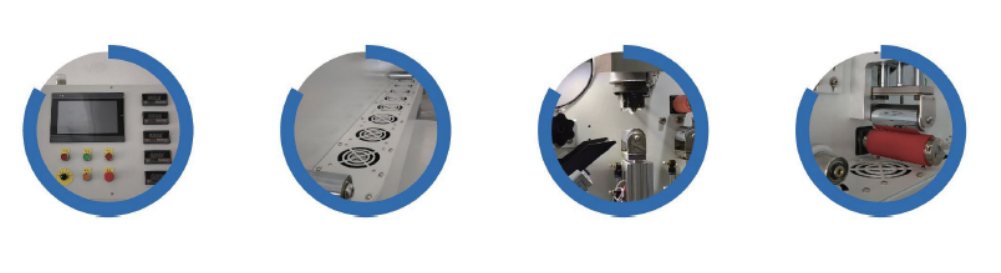

3. The operation panel is simple and practical, easy to learn and master. Accurately record the number of coated meters and adjust the thickness after precise function adjustment.

4. Quantitative production to solve the pressure of minimum order and inventory.

5. Stable and fast feeding speed, comprehensively improving production efficiency.

6. Fixed width mold coating, achieving debugging free, uniform coating, no glue lines, and no glue overflow.

7. Double disc feeding achieves non-stop production and zero waste.

Advantages of laser edge sealing:

1. "0" glue line, the product has a beautiful appearance, smooth chamfers, and comfortable hand feel.

2. Heat resistant, moisture resistant, mold resistant, and stain resistant.

3. As it is a riveted connection, even after years of use, the laser edge banding remains firmly attached and will not age or crack.

4. Laser edge sealing is a permanent edge sealing solution that completely releases formaldehyde and seals it inside the board, without polluting the air.

|

Item |

YT-FB100 |

|

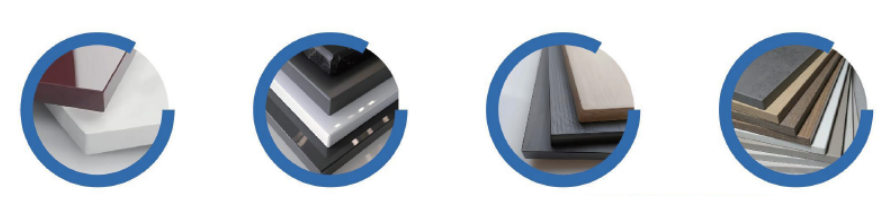

Types of edge banding |

Thermoplastic materials such as PVC,ASB,PP, etc |

|

Feed speed (m/min) |

MAX 30m/min |

|

Edge banding thickness(mm) |

0.5-3.0mm |

|

Coating amount of functional layer (g) |

50g-260g |

|

Coating width(mm) |

16-60mm,different molds achieve different widths of coating |

|

Maximum diameter of coil (mm ) |

800mm |

|

Machine weight (kg) |

900kg |

|

Machine size (lxw ) |

4.7mx1.0m |

|

Total power (w) |

7000w |

|

Air pressure (MPa) |

0.6mpa |