Categories

New Blog

Hot melt adhesive fiber spray gun: Enables pinhole-free garment shaping and more precise adhesive application for diapers

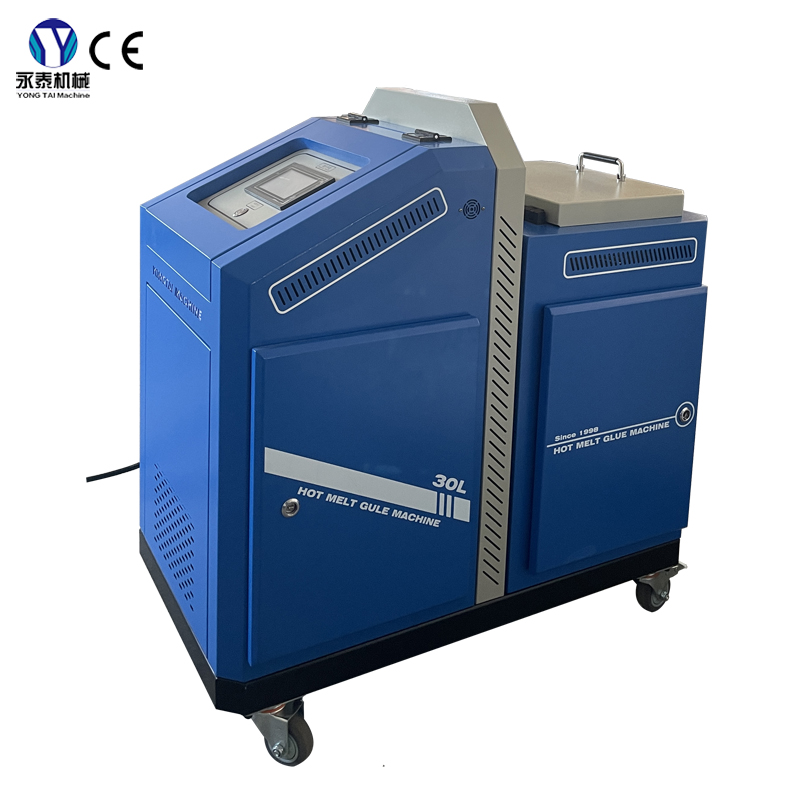

November 11 , 2025In the production of textiles and daily necessities, hot melt adhesive fiber spray guns are gradually replacing traditional needle-sewing and rough adhesive application methods with their triple advantages of high efficiency, precision and environmental protection. They have become key equipment for promoting the upgrading of industry processes, especially showing significant value in clothing detailing and the production of maternal and infant products.

In garment production, waistband fastening and tie shaping have long relied on manual sewing: waistband splicing requires repeated alignment of seams, and tie lining shaping is prone to wrinkling due to overly dense stitches. This not only limits the average daily production capacity to only 300-500 pieces per person, but also results in needle hole residue damaging the texture of high-end fabrics such as silk and acetate fiber. Hot melt adhesive fiber spray guns, through an intelligent temperature control system (adapting to different adhesive melting points of 180-220℃), melt the adhesive and atomize it into 0.05-0.1mm fiber threads, precisely spraying them onto the fabric bonding surface. Curing occurs after pressing for 3-5 seconds.Its bonding strength reaches 50N/25mm, comparable to needle and thread sewing, and it is suitable for easily deformable fabrics such as knitted fabrics and elastic fabrics, avoiding fabric stretching and deformation caused by seams. Currently, leading apparel companies that have introduced this equipment have seen their production line efficiency increase by more than 3 times, labor costs decrease by 40%, and the quality control pass rate of high-end apparel increase to 98%.

Diaper production demands stricter requirements for coating precision and safety: core misalignment can lead to uneven absorption, while excess adhesive can irritate a baby's skin. The hot melt adhesive fiber spray gun, equipped with a high-precision flow valve, achieves point-to-point adhesive application with an accuracy of 0.02ml/point at critical areas such as the diaper core edges and leak-proof side panels. The adhesive line is as fine as 0.1mm with no excess adhesive, increasing the core fixation pass rate from 92% with traditional processes to 99.5%. Simultaneously, the equipment is compatible with low-VOC environmentally friendly hot melt adhesives, with harmful substance release levels below 5mg/kg, meeting EU CE standards for maternal and infant safety and helping companies overcome export trade barriers.

From quality upgrades in garment detailing to safety assurance in the production of maternal and infant products, hot melt adhesive fiber spray guns, with their core advantages of being needle-free, precise, and environmentally friendly, have reshaped the bonding process logic of the textile and daily necessities industry, providing practical solutions for enterprises to reduce costs, increase efficiency, and achieve green production.