Categories

New Blog

The key to quality assurance of medical protective clothing: technological breakthroughs and applications of hot melt adhesive machines

September 24 , 2025In the production chain of medical protective clothing, hot melt adhesive machines are key equipment that determines the level of product protection. With precise and efficient bonding technology, they build the "first barrier" for medical staff against germs. Medical protective clothing has extremely high sealing requirements, especially key parts such as seams, cuffs, ankles and plackets. Once there are gaps, body fluids may penetrate. The hot melt adhesive machine perfectly solves this industry pain point by virtue of its unique working principle.

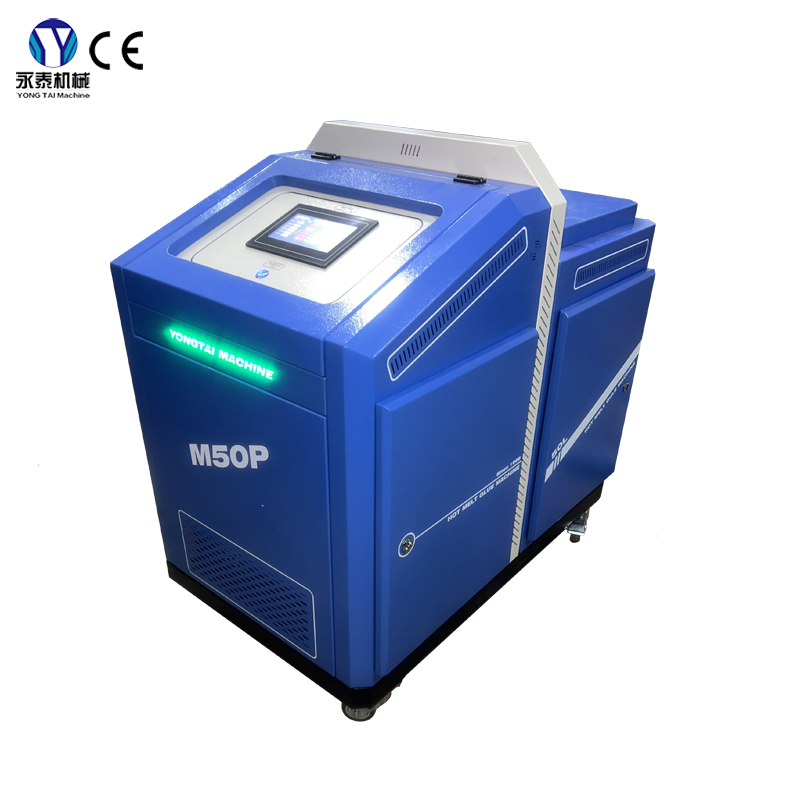

This equipment uses environmentally friendly solid hot-melt adhesive as raw material, accurately heats the adhesive to a molten state of 160-180°C through an intelligent heating module, and then uses a coating system composed of a high-precision gear pump and an alloy die to coat the liquid adhesive in a uniform film or line on the surface of SMS non-woven fabrics, PE films and other substrates. The high-end model is equipped with a PID temperature control system that can control temperature fluctuations within ±1°C, and cooperates with the servo motor-driven feeding mechanism to ensure that the error in the amount of glue applied per meter does not exceed 2%, avoiding potential protection risks caused by uneven glue application.

In actual production, hot melt adhesive machines have a wide range of application scenarios. From the interlayer compounding of the SMS non-woven fabric on the main body of the protective clothing, to the fitting of the waterproof and breathable membrane, to the sealing and bonding of the elastic strips to the cuffs and ankles, everything depends on its stable operation. Compared with traditional needle and thread sutures, hot melt adhesive bonding has no pinholes, and after curing, the adhesive layer has excellent water resistance and high and low temperature resistance. It can still maintain good bonding strength in an environment of - 30°C to 80°C, and there is no solvent evaporation. It fully complies with the strict environmental protection and safety standards of the medical industry.

Hot melt adhesive machines continue to iterate towards automation and high precision. Some new equipment has achieved intelligent linkage with the production line. Gluing parameters can be adjusted in real time through the PLC control system, and the visual inspection module can automatically eliminate unqualified products, greatly improving production efficiency and product qualification rate, and becoming an important support for promoting the high-quality development of the medical protective clothing industry.