Categories

New Blog

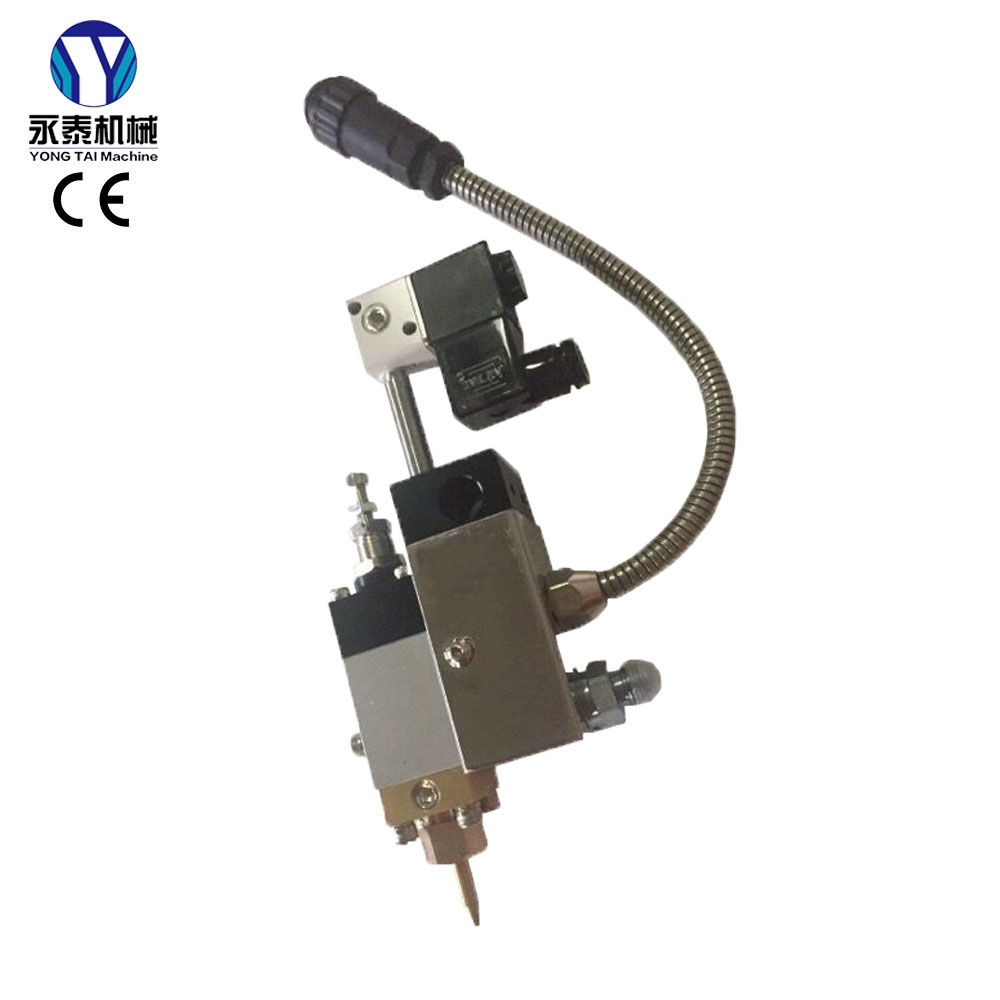

Clear ing Nozzle Assembly

November 18 , 2021Clear ing Nozzle Assembly

Nozzle will be jammed if filter assembly is blocked or broken, or if chars exist in hose/glue tube or nozzle assembly.

Chars is formed because hot melt is overheated. Sometimes in these circumstances hose/glue tube and nozzle assembly need to be changed completely.

Heat the nozzle assembly to desired temperature.

-Minimize the air pressure of the cylinder pump of the hydraulic system.

Set the air valve for the nozzle assembly at desired pressure. Action the nozzle assembly to release the compressed air inside it.

-Minimize the air pressure of the nozzle assembly, detach the nozzle assembly from hose/ glue tube

-Disassemble the nozzle assembly into heating section and spraying section. Take filter web from it. Check it if broken.Replace it if necessary. If only some impurities gather are jammed there. Put the filter assembly into clean solvent and clear it with soft brush, And clean it with clean cloth.The screw nut tightens nozzle. Unscrew the screw nut with a monkey wrench and take the nozzle out of the screw nut.Remove jammed foreign matters or chars by putting a thin, long needle through the small hole of the nozzle (disc or

tip)

Note: Never use a sharp drill bit to clear the holes. A damaged nozzle will lead to unsmooth application

Note2: When clearing the nozzle of an applicator, please follow the below method.

(1) Heat the nozzle with fumeless hot air gun, and clean it with clean cloth .

(2) Soak the nozzle in clean solvent and clear it with ultrasonic device, or

(3)Soak the nozzle in certain amount of chemical cleaner.

-Reassemble the nozzle to the nozzle assembly, And reunite the heating section and the spraying section. Install the filter assembly before reassembling.